PriceList for Calcined Alumina For Ic Substrates - Calcined Alumina (RA) Series for Refractory Materials – Yufa

PriceList for Calcined Alumina For Ic Substrates - Calcined Alumina (RA) Series for Refractory Materials – Yufa Detail:

Specification

| Model No. | Chemical Composition(%) | True Density | Apparent Density | Grain Size | +325 Mesh | Original Crystal | Water Absorption | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

<% | D50(μm) | % | |||

| RA1G | 99.5 | 0.15 | 0.04 | 0.10 | 0.15 | 3.92 | 0.7 | 1.5-2.2 | 1 | ~1.0 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Good particle size distribution 5. High activity |

Used to produce various high-end refractory materials | |

| RA2GL | 99.5 | 0.15 | 0.04 | 0.10 | 0.15 | 3.94 | 0.7 | 2.3-2.7 | 1 | ~2.3 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Good particle size distribution 5. High activity |

||

| RA2G | 99.5 | 0.15 | 0.05 | 0.15 | 0.1 | 3.95 | 0.85 | 3.0-3.6 | 2 | 2.5-3.0 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Reasonable particle size distribution 5. Certain activity |

||

| RA3GD | 99.5 | 0.08 | 0.04 | 0.10 | 0.1 | 3.95 | 0.83 | 4.0-5.0 | 2 | 4.0-4.5 | 1. Grinding, low sodium 2. High calcination temperature 3. Moderate primary crystal size 4. Good fluidity 5. Large bulk density |

||

| RA3G | 99.5 | 0.15 | 0.05 | 0.25 | 0.1 | 3.93 | 0.83 | 4.0-5.0 | 3 | 4.0-4.5 | T18-22 | 1. Grinding 2. Medium sodium 3. High calcination temperature 4. Moderate primary crystal size 5. Good fluidity 6. Large bulk density |

|

| RA5G | 99.5 | 0.15 | 0.05 | 0.25 | 0.1 | 3.93 | 0.85 | 5.6-6.6 | 3 | 5.0-6.0 | 1. Grinding 2. Medium sodium 3. High calcination temperature 4. Large primary crystal size 5. Good fluidity 6. Large bulk density |

||

Applications

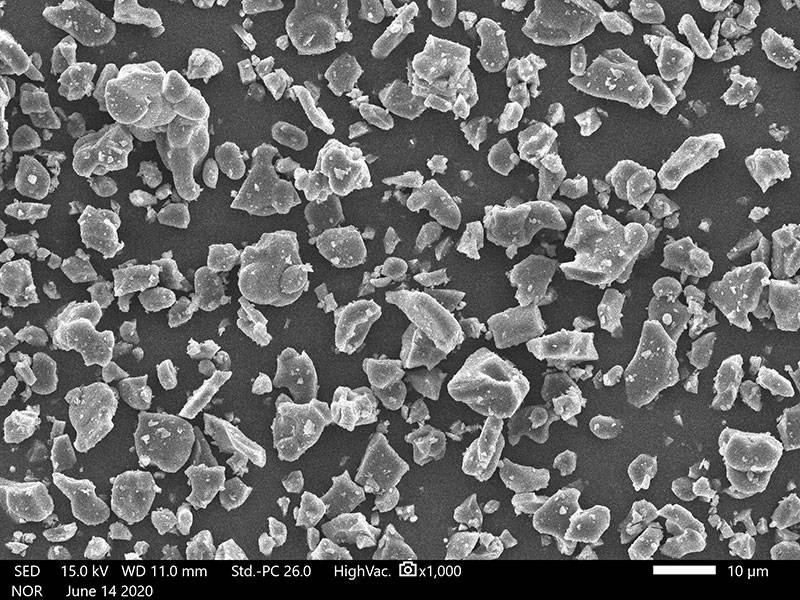

Product detail pictures:

Related Product Guide:

All we do is usually affiliated with our tenet " Buyer to start with, Belief to start with, devoting about the food packaging and environmental defense for PriceList for Calcined Alumina For Ic Substrates - Calcined Alumina (RA) Series for Refractory Materials – Yufa , The product will supply to all over the world, such as: Vancouver, Frankfurt, Croatia, We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will be more conveniently to service our customers.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.

Write your message here and send it to us