OEM Supply Ceramic Granulation Powder - Low Sodium Calcined Alumina (CA) Series for Ceramics – Yufa

OEM Supply Ceramic Granulation Powder - Low Sodium Calcined Alumina (CA) Series for Ceramics – Yufa Detail:

Applications

| Model No. | Chemical Composition(%) | True Density | Apparent Density | Grain Size D50 | +325 Mesh | Original Crystal D50 | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

<% | D50(μm) | |||

| CA1A | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.97 | >0.95 | ~70 | 5.0-6.0 | 1. High temperature calcination 2. Low sodium 3. Large crystal 4. High conversion rate 5. Stable shrinkage. Good fluidity 6. High insulation performance 7. High mechanical strength |

1. High-performance ceramics, such as vacuum tubes 2. Especially suitable for hot -pressing casting process |

|

| CA1D | 99.5 | 0.05 | 0.03 | 0.08 | 0.1 | 3.95 | >0.90 | 3.0-4.0 | 1. Low sodium 2. Moderate crystal size 3. Good particle size distribution 4. Small shrinkage and stability |

1. Spark plugs 2. Vacuum tubes 3. Wear-resistant ceramics, etc. 4. More suitable for static pressure, dry-pressing and other forming processes |

||

| CA1 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.95 | >0.90 | 3.0-3.8 | 1. Static kiln calcination 2. Low sodium 3. Moderate crystal size 4. Good particle size distribution 5. High porcelain density |

1. Mainly used in electronic ceramics 2. Especially suitable for Hot die casting process |

||

| CA2 | 99.5 | 0.08 | 0.03 | 0.08 | 0.1 | 3.96 | >0.90 | 2.8-3.8 | 1. Low sodium 2. Strict crystal size control 3. Good fluidity 4. Stable shrinkage |

1. Electronic ceramics, structural ceramics 2. Especially suitable for Hot die casting process |

||

| CA2G | 0.15 | >0.90 | 3.0-3.5 | < 3.0 | 1. CA2 full grinding 2. Particle size control stability 3. Low sodium 4. Shrinkage stability |

1. Electronic ceramics 2. Structural ceramics, more suitable for making ceramic rollers |

||||||

| CA3 | 99.5 | 0.05 | 0.03 | 0.04 | 0.1 | 3.96 | >0.85 | ~70 | 2.0-2.6 | 1. Strict control of firing temperature 2. Small crystal size 3. Good particle distribution 4. Pretty-low sodium |

Suitable for electronic ceramics, such as IC substrates | |

| CA3G | 0.1 | 2.4-2.9 | <1.0 | Fully grinding of CA3 | ||||||||

| CA4 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.93 | >0.90 | ~70 | 1.0-1.8 | 1. Good activity 2. Low sodium 3. High density after firing 4. Stable shrinkage 5. High mechanical strength |

1. Structural ceramics 2. Electronic ceramics 3. 99 alumina ceramic granulation powder material 4. Suitable for extrusion molding process as well |

|

| CA4G | 0.1 | >0.60 | 1.5-2.2 | <1.0 | Fully grinding of CA4 | |||||||

| CA5 | 99.5 | 0.05 | 0.02 | 0.05 | 0.1 | 3.92 | ~70 | <1.0 | 1. Small & unifrom crystal size 2. Good activity |

99 alumina ceramic hot die casting process, etc | ||

| CA5G | 1-1.3 | <1.0 | 1. Small & unifrom crystal size 2. Good activity 3. Fully grinding 4. Narrow particle size distribution |

Ceramic filter,etc | ||||||||

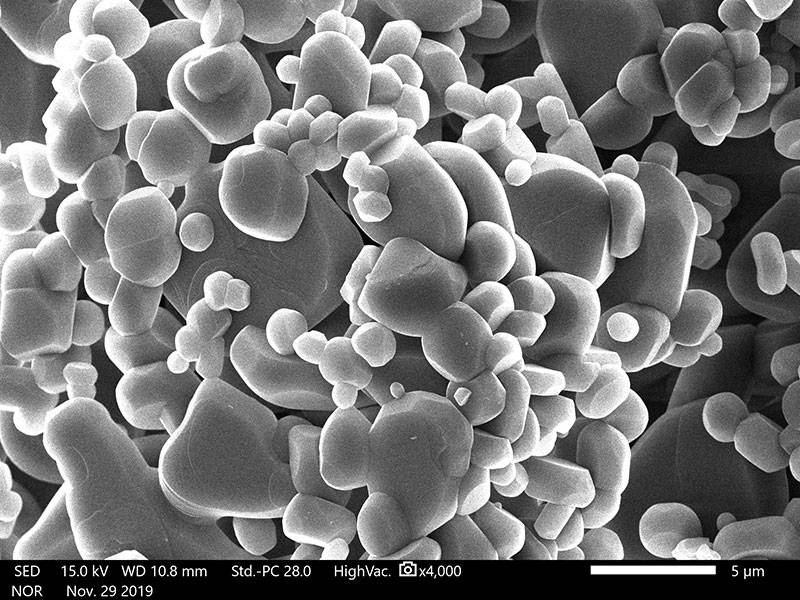

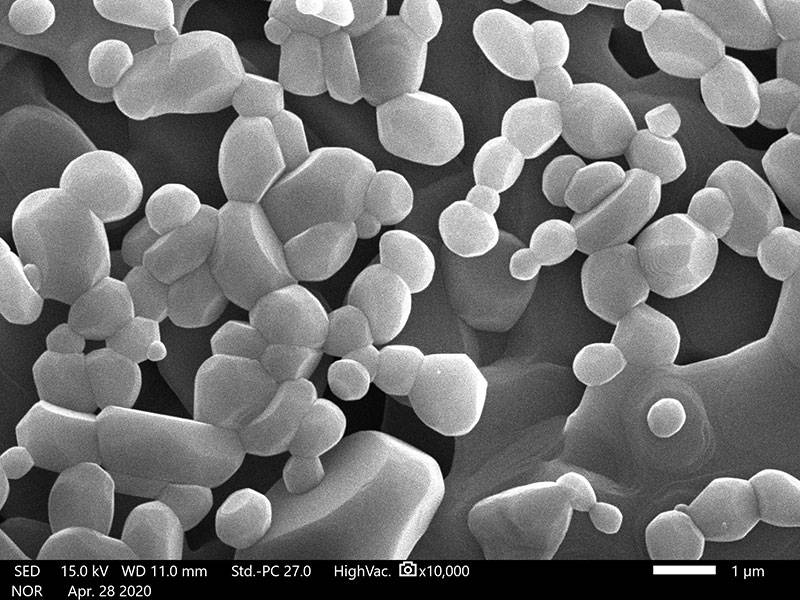

Product detail pictures:

Related Product Guide:

Our products are greatly recognized and trustworthy by users and will fulfill continually shifting economic and social requires for OEM Supply Ceramic Granulation Powder - Low Sodium Calcined Alumina (CA) Series for Ceramics – Yufa , The product will supply to all over the world, such as: Belgium, Dubai, Mexico, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.

Write your message here and send it to us