OEM Manufacturer Ceramic Insulators Powder - Calcined Alumina (FA) Series for Heat Conduction – Yufa

OEM Manufacturer Ceramic Insulators Powder - Calcined Alumina (FA) Series for Heat Conduction – Yufa Detail:

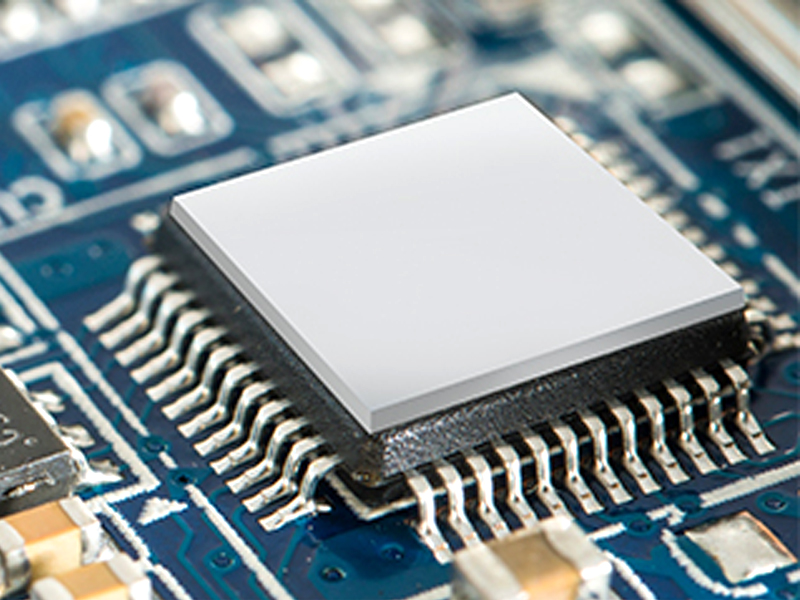

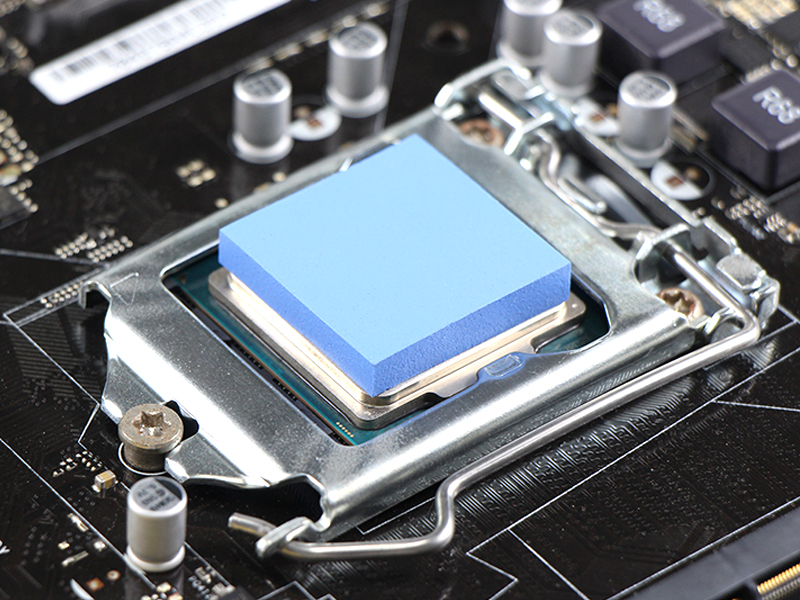

Applications

| Chemical Composition (%) | Ture Density | Apparent Density | Grain Size | Original Crystal | Oil Absorption Rate | Conversion Rate | +325 | Residual Boron | Features | Recommended Applications | |||||

| Model No. | Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

D50 (μm) |

ml | ≥% | <% | <% | ||

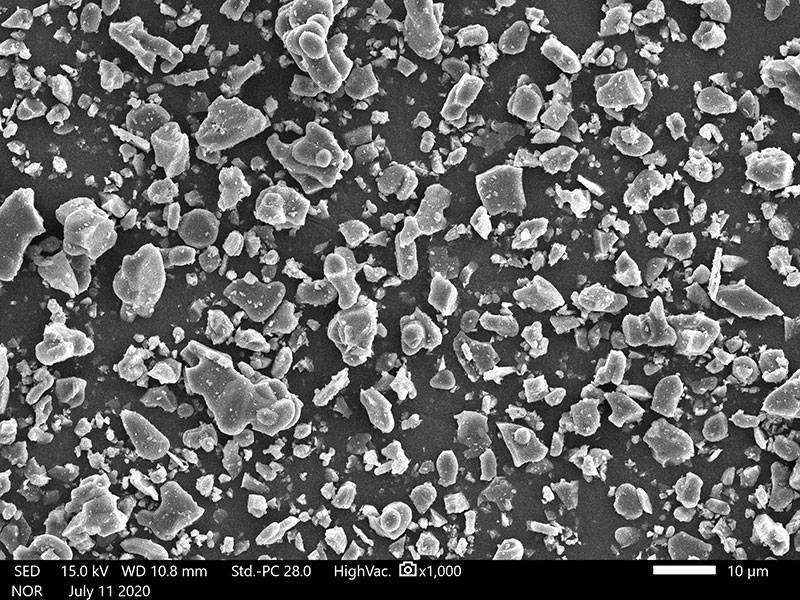

| FA3 | 99.5 | 0.1 | 0.03 | 0.08 | 0.1 | 3.96 | >0.85 | ~2.8 | 2.1-2.7 | <17 | ≥95 | 0.5 | / | 1. High temperature calcination 2. Deep grinding & Good flowability 3. Reasonable particle size distribution 4. Good thermo conductivity |

1. It can be used to thermal conductive materials 2. It suitable for ceramic coatings etc. |

| FA4 | 99.5 | 0.05 | 0.03 | 0.08 | 0.1 | 3.96 | >0.85 | ~4 | 3.6-4.5 | 13-15 | ≥95 | 0.5 | 0.02 | 1. High temperture clacination 2. Deep grinding 3. Reasonable grain size & crystal shape distribution 4. Good flowability & Good thermo conductivity |

|

| FA5 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~6 | 5.5-6 | ≤14 | ≥95 | 0.5 | 0.1 | 1. High temperature calcination 2. Deep grinding 3. Larger crystal paticle 4. Reasonable paricle distribution 5. High apparent density 6. Good flowability & good themo conductivity |

|

| FA10 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~10 | 8-10 | / | ≥95 | 1 | 0.1 | 1. Large crystal particle 2. Reasonable particle size distribution 3. High apparent density 4. Excellent flowability 5. Excellent thermo conductivity |

|

| FA15 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~13 | 10-13 | / | ≥95 | 1 | 0.1 | 1. Special production process 2. Large crystal particle 3. Good flowability 4. Good thermoconductivity |

|

Product detail pictures:

Related Product Guide:

We take pleasure in an extremely fantastic standing among the our prospects for our great product top quality, competitive cost and the finest support for OEM Manufacturer Ceramic Insulators Powder - Calcined Alumina (FA) Series for Heat Conduction – Yufa , The product will supply to all over the world, such as: Palestine, Bolivia, Ottawa, We welcome you to visit our company, factory and our showroom displayed various products that will meet your expectation, meanwhile, it is convenient to visit our website, our sales staff will try their efforts to provide you the best service. If you need more information, please do not hesitate to contact us by E-mail or telephone.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.

Write your message here and send it to us