OEM Factory for Ceramic Insulators - Calcined Alumina (FA) Series for Heat Conduction – Yufa

OEM Factory for Ceramic Insulators - Calcined Alumina (FA) Series for Heat Conduction – Yufa Detail:

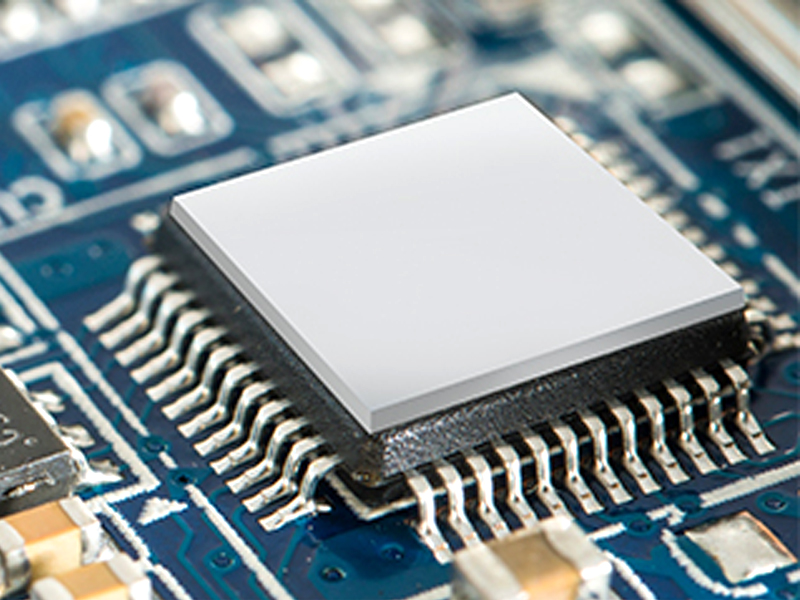

Applications

| Chemical Composition (%) | Ture Density | Apparent Density | Grain Size | Original Crystal | Oil Absorption Rate | Conversion Rate | +325 | Residual Boron | Features | Recommended Applications | |||||

| Model No. | Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

D50 (μm) |

ml | ≥% | <% | <% | ||

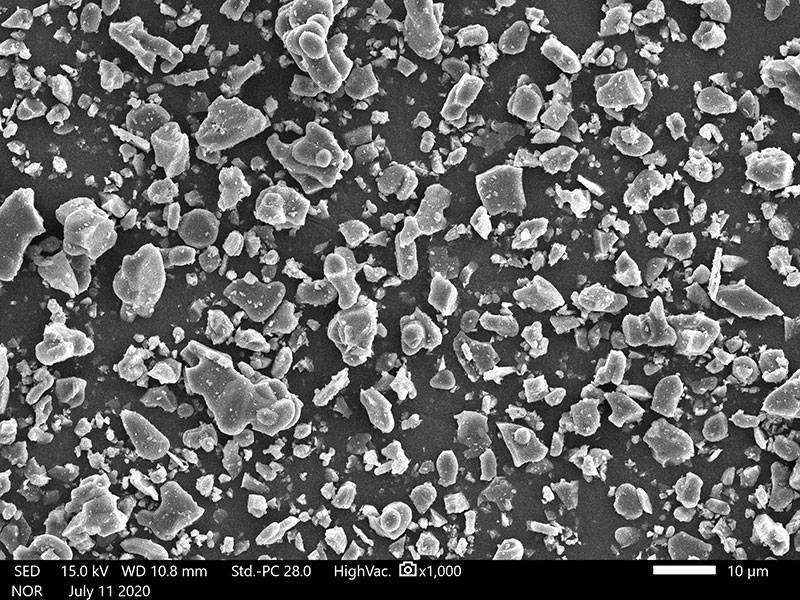

| FA3 | 99.5 | 0.1 | 0.03 | 0.08 | 0.1 | 3.96 | >0.85 | ~2.8 | 2.1-2.7 | <17 | ≥95 | 0.5 | / | 1. High temperature calcination 2. Deep grinding & Good flowability 3. Reasonable particle size distribution 4. Good thermo conductivity |

1. It can be used to thermal conductive materials 2. It suitable for ceramic coatings etc. |

| FA4 | 99.5 | 0.05 | 0.03 | 0.08 | 0.1 | 3.96 | >0.85 | ~4 | 3.6-4.5 | 13-15 | ≥95 | 0.5 | 0.02 | 1. High temperture clacination 2. Deep grinding 3. Reasonable grain size & crystal shape distribution 4. Good flowability & Good thermo conductivity |

|

| FA5 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~6 | 5.5-6 | ≤14 | ≥95 | 0.5 | 0.1 | 1. High temperature calcination 2. Deep grinding 3. Larger crystal paticle 4. Reasonable paricle distribution 5. High apparent density 6. Good flowability & good themo conductivity |

|

| FA10 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~10 | 8-10 | / | ≥95 | 1 | 0.1 | 1. Large crystal particle 2. Reasonable particle size distribution 3. High apparent density 4. Excellent flowability 5. Excellent thermo conductivity |

|

| FA15 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~13 | 10-13 | / | ≥95 | 1 | 0.1 | 1. Special production process 2. Large crystal particle 3. Good flowability 4. Good thermoconductivity |

|

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, believe in the 1st and management the advanced" for OEM Factory for Ceramic Insulators - Calcined Alumina (FA) Series for Heat Conduction – Yufa , The product will supply to all over the world, such as: Greek, Angola, Serbia, Our Company has professional engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the products, Please feel free to contact us.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly

Write your message here and send it to us