Manufacturer for Artificial Dense Corundum - Fused Dense Corundum – Yufa

Manufacturer for Artificial Dense Corundum - Fused Dense Corundum – Yufa Detail:

Applications

The fused dense corundum is one of the first-choice raw materials for the production of high-performance unshaped and shaped refractory materials.

1.It’s widely used in industries such as steel, cement, ceramics, petrochemicals, etc.

2.It’s main raw materials for making blast furnace iron trough castables, ladle castables, ramming materials, preforms and other unshaped refractory materials.

3.It’s an ideal raw materials for various shaped products such as three continuous casting pieces, aire bricks, nozzle block bricks, etc.

4.It’s also an excellent material for making steel-making long nozzles, skateboards and various corundum bricks.

Grit and Fine Powder

0.1-0 mm, 0.2-0 mm, 0.5-0 mm, 1-0 mm, 1-0.5 mm, 3-1 mm, 5-3 mm, 8-5 mm, 10-5 mm, 25-10 mm, 100 mesh, 200 mesh, 325 mesh ……

Other spec are available upon request.

Product Advantages

1.Select high-quality industrial alumina, which is high purity, low impurities. YUFA control quality from raw materials.

2.Fused dense alumina has a high melting point and a high-volume density, which melted at high temperature and constant temperature in an advanced electric melting tilting furnace.

Melting Process

Tilting Furnace – Transfert – Cool Down – Barmac Crusher & Sorting – Sand Making – Warehouse

QC

To the fused dense corundum, the chemical composition of Al2O3, SiO2, Fe2O3,K2O,Na2O need to be tested, also very strick with the inspection of the bulk density.

Chemical Composition

|

Chemical Composition |

Grit > 0.1mm |

Typical Value |

Fine Powder ≤ 0.1mm |

Typical Value |

|

Al2O3%≥ |

99.2 |

99.6 |

99 |

99.4 |

|

SiO2%≤ |

0.5 |

0.4 |

0.7 |

0.5 |

|

Fe2O3%≤ |

0.1 |

0.03 |

0.1 |

0.05 |

|

TiO2%≤ |

0.1 |

0.05 |

0.1 |

0.05 |

|

CaO%≤ |

||||

|

MgO%≤ |

||||

|

Na2O%≤ |

||||

|

C%≤ |

0.08 |

0.12 |

0.1 |

|

|

Apparent porosity %≤ |

2 |

0.8 |

2 |

0.8 |

|

Bulk Density g/cm3≥ |

3.9 |

3.93 |

|

|

|

True Density g/cm3≥ |

3.96 |

3.99 |

3.96 |

3.98 |

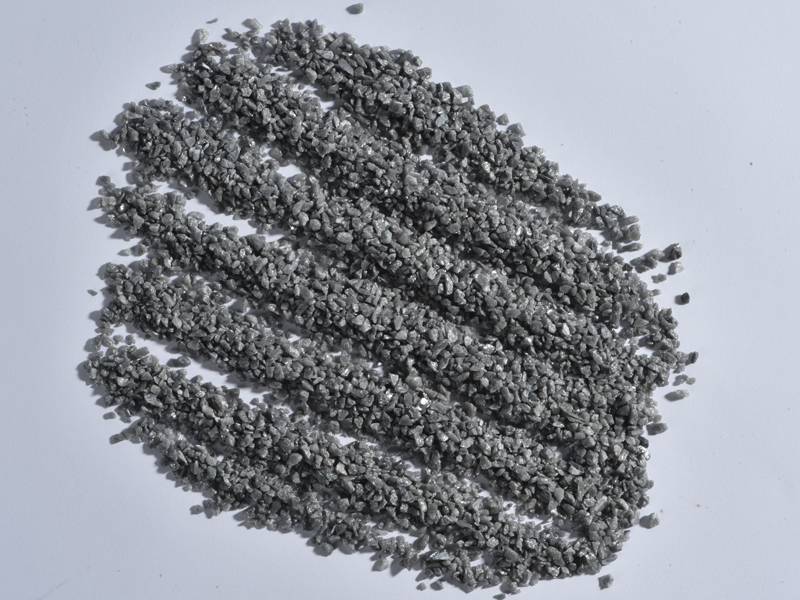

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for Manufacturer for Artificial Dense Corundum - Fused Dense Corundum – Yufa , The product will supply to all over the world, such as: Bolivia, Panama, Colombia, Our professional engineering group will always be ready to serve you for consultation and feedback. We are able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to give you the ideal service and goods. For anyone who is thinking about our company and merchandise, please contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Please feel free to get in touch with us for business and we believe we are going to share the top trading practical experience with all our merchants.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.