Free sample for Ceramic Insulator Tube - Low-Sodium Calcined Alumina (HA) Series Coarse Powder – Yufa

Free sample for Ceramic Insulator Tube - Low-Sodium Calcined Alumina (HA) Series Coarse Powder – Yufa Detail:

| Model No. | Chemical Composition (%) | True Density | Apparent Density | Original Crystal | Conversion Rate | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

≥% | |||

| HA5 | 99.5 | 0.05 | 0.02 | 0.12 | 0.1 | 3.95 | 0.9 | 6.5-8.0 | 95 | 1. Unground & Low sodiume 2. Near-spherical crystal 3. Large crystal & Fully developed 4. Less shrinkage & Large output 5. Good quality stability |

1. Suitable for high-performance ceramics 2. Suitable for rough polishing 3. Suitable for refractory materials 4. Suitable for thermal conducting fillers 5. Suitable for wear-resistant coating industries |

| HA4 | 99.5 | 0.05 | 0.02 | 0.10 | 0.1 | 3.95 | 0.9 | 5.5-6.5 | |||

| HA3 | 99.5 | 0.05 | 0.02 | 0.12 | 0.1 | 3.95 | 0.9 | 4.5-5.6 | |||

| HA2 | 99.5 | 0.05 | 0.02 | 0.15 | 0.1 | 3.93 | 0.9 | 3.0-4.0 | 93 | 1. Unground, medium sodium 2. Near-spherical crystal 3. Crystal range of 2-3 μm 4. Good sinterability & Large output 5. Good quality stability. |

Suitable for ceramics and refractory industries. |

| HA1 | 99.7 | 0.05 | 0.02 | 0.01 | 0.1 | 3.93 | 0.9 | ~2 | 93 | 1. Extremely low impurities 2. Na2O≤ 0.01% 3. High conversion rate 4. Fine and uniform crystal |

1. Suitable for high-performance ceramics 2. Suitable for preparation of refractory powder 3. Suitable for wear-resistance coatings industries, etc. |

| HA2X | 99.5 | 0.10 | 0.02 | 0.08 | 0.1 | 3.95 | 0.9 | ~3 | 95 | 1. Easy to grind 2. Extremely low impurities 3. Good crystal sphericity 4. Narrow cystal distribution 5. Less shrinkage & Large output 6. Good quality stability |

1. Suitable for high-performance ceramics 2. Suitable for LCD glass, refractory materials 3. Suitable for thermally conductive fillers 4. Suitable for medium polishing materials industries, etc. |

| HA1X | 99.5 | 0.12 | 0.02 | 0.10 | 0.1 | 3.93 | 0.9 | ~2.3 | 93 | 1. Easy to grind & Low sodium 2. Good sphericity 3. Narrow cystal distribution 4. Small crystal & Good flowability 5. Large output & Good quality stability |

1. Suitable for the production of high-performance ceramics and refractory fine powder 2. It can be used in alumina ball |

| HA0X | 99.5 | 0.08 | 0.02 | 0.10 | 0.1 | 3.9 | 0.9 | ~1 | 92 | 1. Small crystal 2. Low impurities. |

1. Suitable for the production of high-performance ceramics and refractory powder preparation 2. It can used to preparation of wear-resistant coatings industries, etc 3. It can be used in alumina ball |

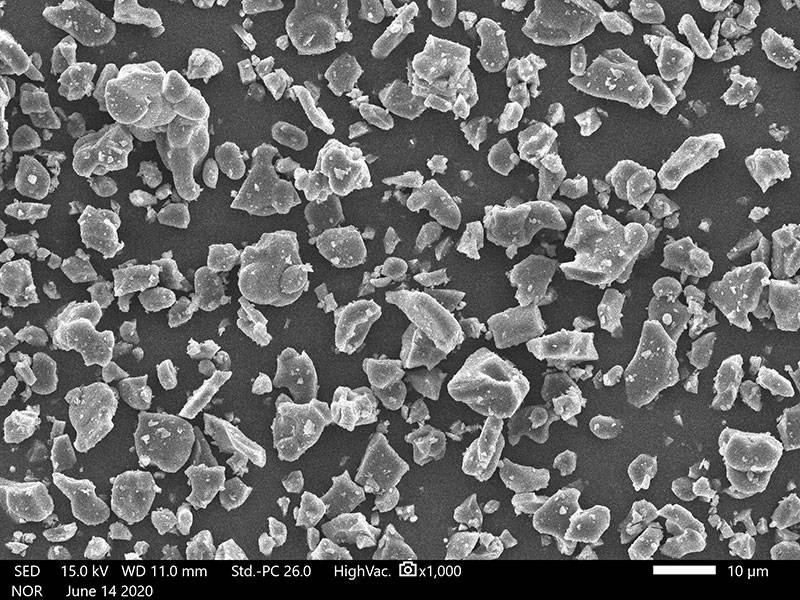

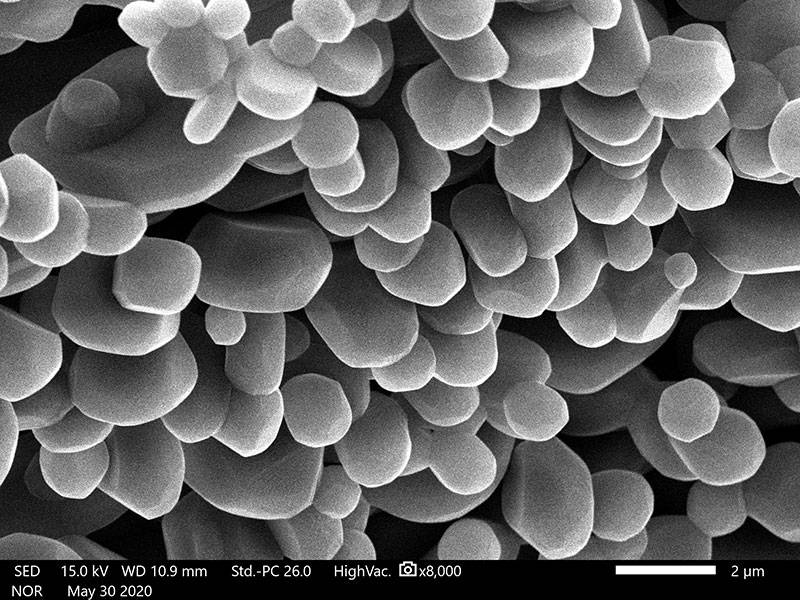

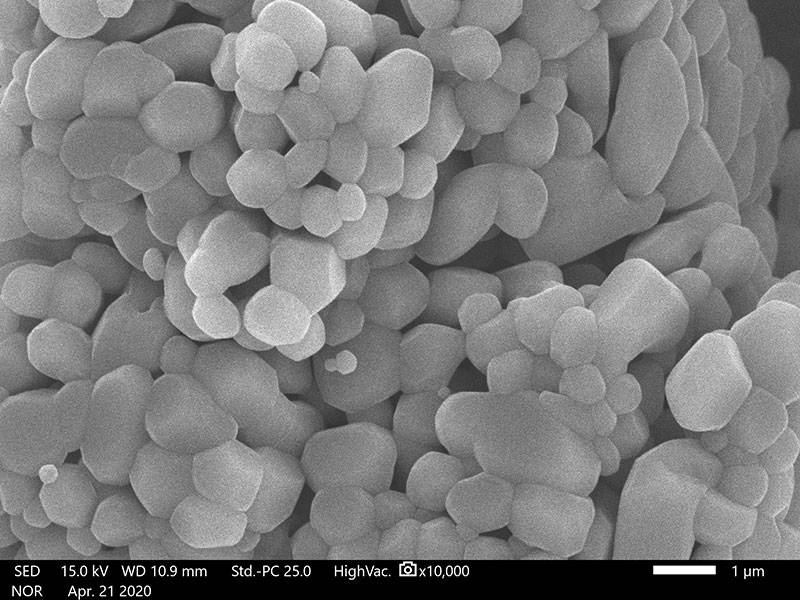

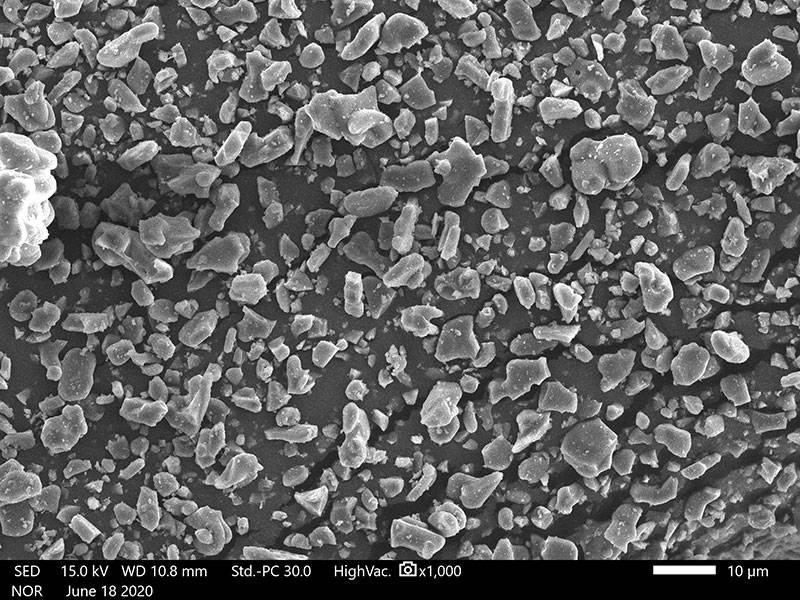

Product detail pictures:

Related Product Guide:

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for Free sample for Ceramic Insulator Tube - Low-Sodium Calcined Alumina (HA) Series Coarse Powder – Yufa , The product will supply to all over the world, such as: Ghana, New York, Las Vegas, We've got sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

Write your message here and send it to us