Factory source Ceramic Thermal Insulator - Calcined Alumina (FA) Series for Heat Conduction – Yufa

Factory source Ceramic Thermal Insulator - Calcined Alumina (FA) Series for Heat Conduction – Yufa Detail:

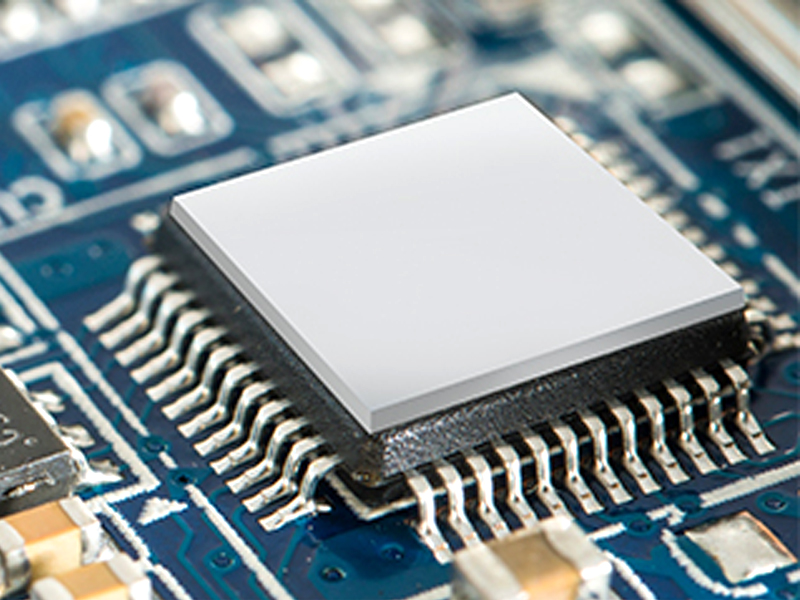

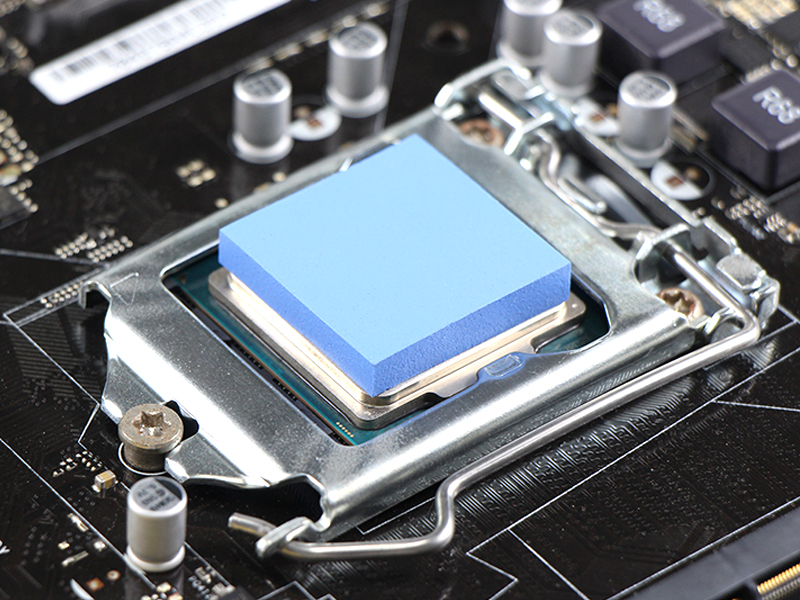

Applications

| Chemical Composition (%) | Ture Density | Apparent Density | Grain Size | Original Crystal | Oil Absorption Rate | Conversion Rate | +325 | Residual Boron | Features | Recommended Applications | |||||

| Model No. | Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

D50 (μm) |

ml | ≥% | <% | <% | ||

| FA3 | 99.5 | 0.1 | 0.03 | 0.08 | 0.1 | 3.96 | >0.85 | ~2.8 | 2.1-2.7 | <17 | ≥95 | 0.5 | / | 1. High temperature calcination 2. Deep grinding & Good flowability 3. Reasonable particle size distribution 4. Good thermo conductivity |

1. It can be used to thermal conductive materials 2. It suitable for ceramic coatings etc. |

| FA4 | 99.5 | 0.05 | 0.03 | 0.08 | 0.1 | 3.96 | >0.85 | ~4 | 3.6-4.5 | 13-15 | ≥95 | 0.5 | 0.02 | 1. High temperture clacination 2. Deep grinding 3. Reasonable grain size & crystal shape distribution 4. Good flowability & Good thermo conductivity |

|

| FA5 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~6 | 5.5-6 | ≤14 | ≥95 | 0.5 | 0.1 | 1. High temperature calcination 2. Deep grinding 3. Larger crystal paticle 4. Reasonable paricle distribution 5. High apparent density 6. Good flowability & good themo conductivity |

|

| FA10 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~10 | 8-10 | / | ≥95 | 1 | 0.1 | 1. Large crystal particle 2. Reasonable particle size distribution 3. High apparent density 4. Excellent flowability 5. Excellent thermo conductivity |

|

| FA15 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~13 | 10-13 | / | ≥95 | 1 | 0.1 | 1. Special production process 2. Large crystal particle 3. Good flowability 4. Good thermoconductivity |

|

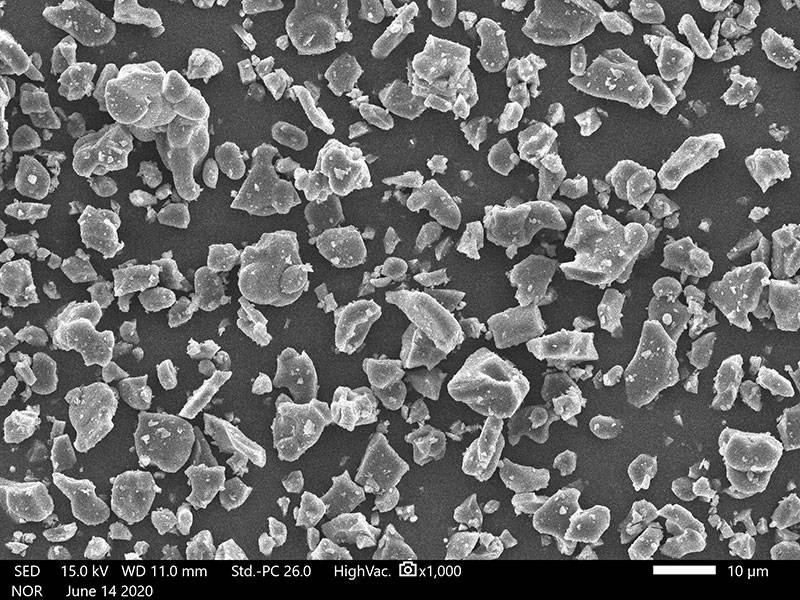

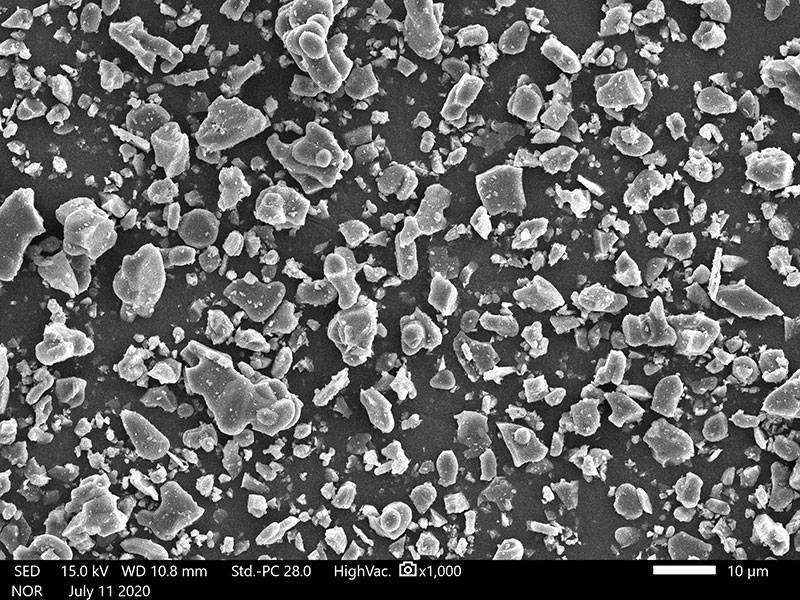

Product detail pictures:

Related Product Guide:

We usually keep on with the principle "Quality To start with, Prestige Supreme". We've been fully committed to offering our purchasers with competitively priced excellent solutions, prompt delivery and skilled support for Factory source Ceramic Thermal Insulator - Calcined Alumina (FA) Series for Heat Conduction – Yufa , The product will supply to all over the world, such as: Mexico, Anguilla, Paris, Our company, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.

Write your message here and send it to us