Best quality Calcined Alumina For Ceramics - Calcined Alumina (RA) Series for Refractory Materials – Yufa

Best quality Calcined Alumina For Ceramics - Calcined Alumina (RA) Series for Refractory Materials – Yufa Detail:

Applications

| Model No. | Chemical Composition(%) | True density | Apparent density | Grain size | +325 mesh | Original Crystal | Water Absorption | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

d50 (μm) |

<% | d50(μm) | % | |||

| RA1G | 99.5 | 0.15 | 0.04 | 0.10 | 0.15 | 3.92 | 0.7 | 1.5-2.2 | 1 | ~1.0 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Good particle size distribution 5. High activity |

Used to produce various high-end refractory materials | |

| RA2GL | 99.5 | 0.15 | 0.04 | 0.10 | 0.15 | 3.94 | 0.7 | 2.3-2.7 | 1 | ~2.3 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Good particle size distribution 5. High activity |

||

| RA2G | 99.5 | 0.15 | 0.05 | 0.15 | 0.1 | 3.95 | 0.85 | 3.0-3.6 | 2 | 2.5-3.0 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Reasonable particle size distribution 5. Certain activity |

||

| RA3GD | 99.5 | 0.08 | 0.04 | 0.10 | 0.1 | 3.95 | 0.83 | 4.0-5.0 | 2 | 4.0-4.5 | 1. Grinding, low sodium 2. High calcination temperature 3. Moderate primary crystal size 4. Good fluidity 5. Large bulk density |

||

| RA3G | 99.5 | 0.15 | 0.05 | 0.25 | 0.1 | 3.93 | 0.83 | 4.0-5.0 | 3 | 4.0-4.5 | T18-22 | 1. Grinding 2. Medium sodium 3. High calcination temperature 4. Moderate primary crystal size 5. Good fluidity 6. Large bulk density |

|

| RA5G | 99.5 | 0.15 | 0.05 | 0.25 | 0.1 | 3.93 | 0.85 | 5.6-6.6 | 3 | 5.0-6.0 | 1. Grinding 2. Medium sodium 3. High calcination temperature 4. Large primary crystal size 5. Good fluidity 6. Large bulk density |

||

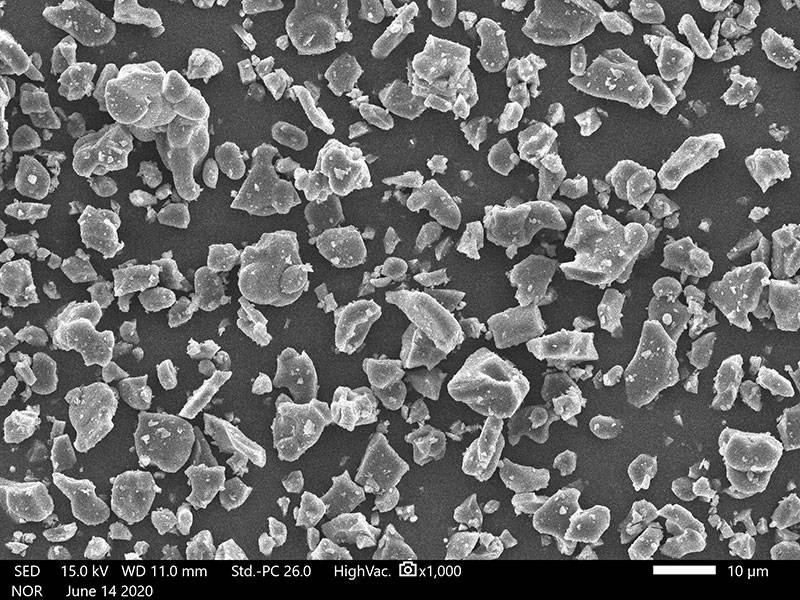

Product detail pictures:

Related Product Guide:

abide by the contract", conforms towards the market requirement, joins during the market competition by its good quality likewise as provides additional comprehensive and great services for customers to let them turn out to be big winner. The pursue of your enterprise, is the clients' fulfillment for Best quality Calcined Alumina For Ceramics - Calcined Alumina (RA) Series for Refractory Materials – Yufa , The product will supply to all over the world, such as: Mozambique, Liverpool, Florida, We have more than 8 years of experience in this industry and have a good reputation in this field. Our products have won praise from customers worldwide. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.

Write your message here and send it to us