2021 High quality Electro Corundum - Fused Dense Corundum – Yufa

2021 High quality Electro Corundum - Fused Dense Corundum – Yufa Detail:

Applications

The fused dense corundum is one of the first-choice raw materials for the production of high-performance unshaped and shaped refractory materials.

1.It’s widely used in industries such as steel, cement, ceramics, petrochemicals, etc.

2.It’s main raw materials for making blast furnace iron trough castables, ladle castables, ramming materials, preforms and other unshaped refractory materials.

3.It’s an ideal raw materials for various shaped products such as three continuous casting pieces, aire bricks, nozzle block bricks, etc.

4.It’s also an excellent material for making steel-making long nozzles, skateboards and various corundum bricks.

Grit and Fine Powder

0.1-0 mm, 0.2-0 mm, 0.5-0 mm, 1-0 mm, 1-0.5 mm, 3-1 mm, 5-3 mm, 8-5 mm, 10-5 mm, 25-10 mm, 100 mesh, 200 mesh, 325 mesh ……

Other spec are available upon request.

Product Advantages

1.Select high-quality industrial alumina, which is high purity, low impurities. YUFA control quality from raw materials.

2.Fused dense alumina has a high melting point and a high-volume density, which melted at high temperature and constant temperature in an advanced electric melting tilting furnace.

Melting Process

Tilting Furnace – Transfert – Cool Down – Barmac Crusher & Sorting – Sand Making – Warehouse

QC

To the fused dense corundum, the chemical composition of Al2O3, SiO2, Fe2O3,K2O,Na2O need to be tested, also very strick with the inspection of the bulk density.

Chemical Composition

|

Chemical Composition |

Grit > 0.1mm |

Typical Value |

Fine Powder ≤ 0.1mm |

Typical Value |

|

Al2O3%≥ |

99.2 |

99.6 |

99 |

99.4 |

|

SiO2%≤ |

0.5 |

0.4 |

0.7 |

0.5 |

|

Fe2O3%≤ |

0.1 |

0.03 |

0.1 |

0.05 |

|

TiO2%≤ |

0.1 |

0.05 |

0.1 |

0.05 |

|

CaO%≤ |

||||

|

MgO%≤ |

||||

|

Na2O%≤ |

||||

|

C%≤ |

0.08 |

0.12 |

0.1 |

|

|

Apparent porosity %≤ |

2 |

0.8 |

2 |

0.8 |

|

Bulk Density g/cm3≥ |

3.9 |

3.93 |

|

|

|

True Density g/cm3≥ |

3.96 |

3.99 |

3.96 |

3.98 |

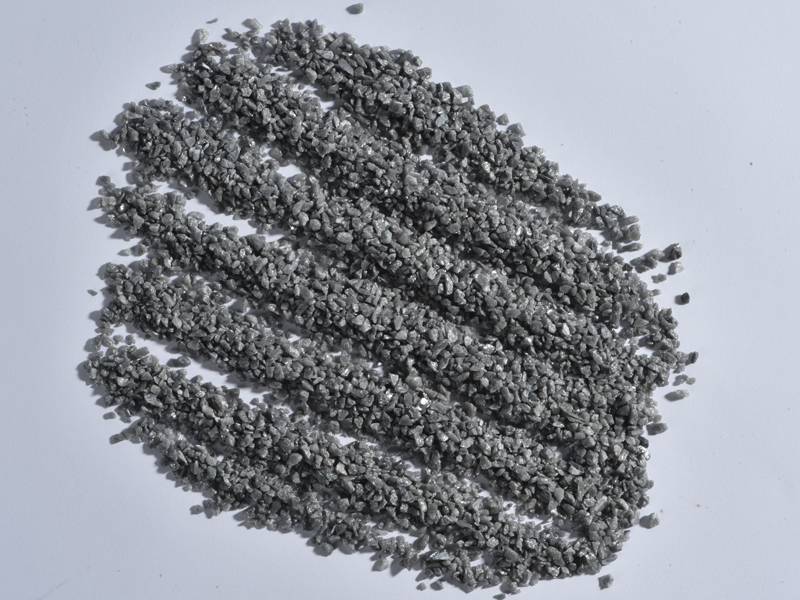

Product detail pictures:

Related Product Guide:

As for aggressive costs, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such high-quality at such rates we have been the lowest around for 2021 High quality Electro Corundum - Fused Dense Corundum – Yufa , The product will supply to all over the world, such as: Bolivia, Mozambique, Latvia, Our mission is "Provide Products with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!