Classification of Fused Spinel and Sintered Spinel

Spinel (MgO·Al2O3, abbreviated as MA) is the only binary compound in the MgO-Al2O3 binary system. It can partially dissolve with MgO and Al2O3 to form a limited solid solution. Corundum (α-Al2O3) solid solution spinel is formed in the Al2O3 rich composition; periclase solid solution spinel is formed in the MgO rich composition. The maximum solid solubility occurs at the two analyzed eutectic temperatures of MA-Al2O3 and MgO-MA, which are 1925 °C and 1995 °C, respectively.

When MgO and Al2A form spinel according to the theoretical composition, it will generate about 8% volume expansion, so it is difficult to densify when sintered, and it is easier to co-dissolve with MgO or Al: the sharp point of solid solution MgO or Al2O3 Spar has better thermal shock stability due to the difference in expansion coefficient between minerals.

According to the synthesis method of spinel, it can be divided into sintered spinel, fused spinel and active spinel, in addition to high-density spinel.

1. Sintered spinel and electrofused spinel are produced by sintering and electrofusion methods, respectively;

2. Active spinel is also synthesized by sintering method, but different from sintered spinel, its synthesis temperature is low (1200-1300 ℃), and the mixture is not completely transformed into spinel, but contains a small amount of free α -Al2O3 and or free MgO, it is mainly used as the matrix of spinel refractories or the production of high-density spinel:

3. The bulk density of high-density spinel is generally greater than 3.40g/cm3, usually made of active spinel powder by pressing Ball or pressed, sintered at a high temperature of about 1700 ° C.

4. Fused spinel is a kind of high-purity synthetic refractory material, which is made of alumina and high-purity light burned magnesium as main raw materials and cooled after melting at a high temperature above 2300 ℃ in an electric arc furnace.

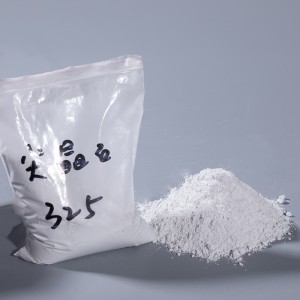

Fused alumina magnesia spinel has high bulk density and has good corrosion resistance, slag resistance and thermal shock stability. The following is a picture of Yufa Group’s fused spinel:

For more details contact Mr. Dr. Arthur.

Email: arthur@yfml.com

Whatapp: 00861583807142

Post time: Aug-27-2022